- A water filter series equipmen

- Cooling tower series equipment

- Filter 1series equipment

- Pure water preparation series

- Dosing, mixing, tumbling serie

- Disinfection series equipment

- Sewage and waste water treatme

- Urban sewage equipment

- Deodorization dust removal ser

- Algae a car transport system

- The fiberglass produ equipment

- Packing series

- Aeration series

- Other

1, Summarize

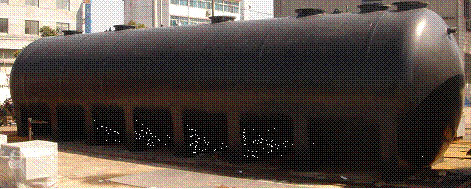

Glass fiber reinforced plastic storage tanks into vertical storage tanks, horizontal machine winding glass fiber reinforced plastic storage tanks, transportation cans, reaction jug, all kinds of chemical equipment, according to the transportation) medium (storage or choose epoxy resin, modification or polyester furan resin, phenolic resin as bond, the resin content from high resistance to corrosion, seepage control layer, lining of the fiber winding strengthening and appearance of protective coating.

2, Characteristics

The proportion of glass fiber reinforced plastic usually for 1.8 2.1, is a quarter of the steel, steel 1/5-than, cast the literary and plastic than strength are high. The thermal expansion coefficient and glass fiber reinforced plastic steel, heat conduction coefficient is approximately only 0.5% of the steel.

Glass fiber reinforced plastic containers, fiber glass tank chemically resistant, long service life: glass fiber reinforced plastic with special decay resistance performance, in the storage corrosive medium, glass fiber reinforced plastic show other materials, the advantage of incomparable excellent resistance to DuoZhong acid, alkali, salt and organic solvents.

Glass fiber reinforced plastic containers, fiber glass tank design flexibility, rigid wall structure performance is excellent: glass fiber reinforced plastic fiber winding can change resin system or reinforced materials to high-speed fiber glass tank and non-standard equipment of the physical and chemical properties, in order to adapt to the different medium and the needs of the working conditions. Through the structure layer thickness, winding Angle and wall thickness structure and design to adjust the bearing capacity of the tank, made for different pressure levels or some special properties of the fiber glass tank and non-standard equipment, this is isotropic metal materials and can't compared to.